As part of the restoration of my '97 XJ600, and honestly a necessity, I'm overhauling the carburetors. This includes disassembling them, cleaning them and reassembling using new gaskets, seals and jets.

Here are Some General Symptoms of Dirty Carbs:

- 1. The bike is hard to start or floods easily

2. The bike leaks fuel out of the carburetors

3. The bike won't idle without the chock on

4. The bike's idle speed is difficult to set and the bike hunts for idle.

5. The bike won't run without consistently giving it throttle.

6. The bike idles low and turning the idle screw makes it jump up to 3k rpm.

7. The bike has trouble idling; it may die at stoplights or when the clutch is pulled

These are the tools I used while disassembling the carbs. Most importantly are a good-fitting, high quality phillips-head screwdriver and a pair of vice grips:

Disassembly:

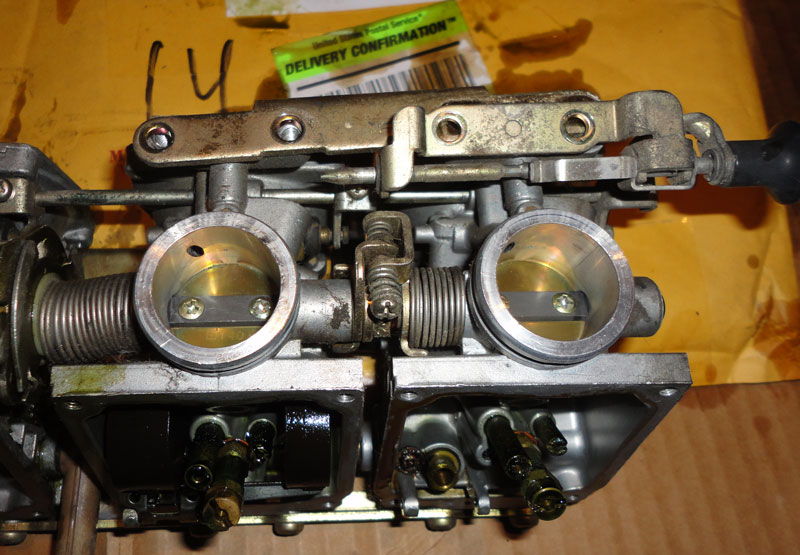

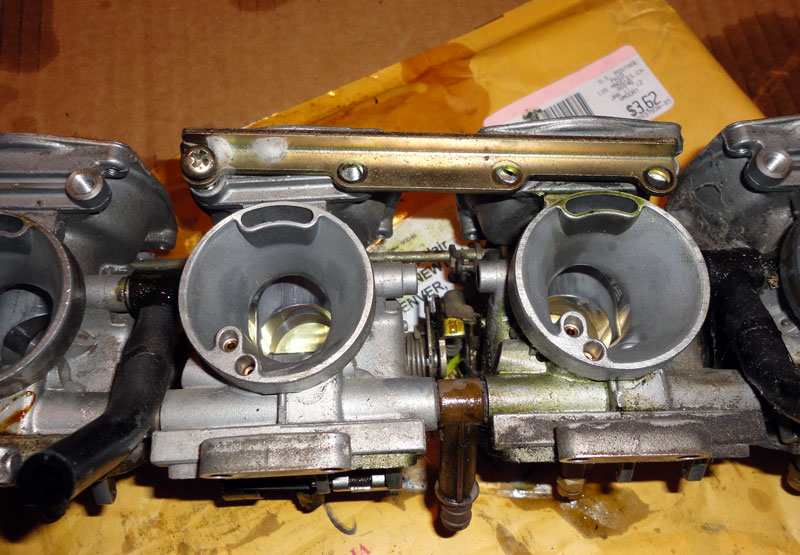

Here are the carburetors, as removed from the bike. Two of the slides are frozen in place, the butterflies don't move smoothly and they've been in a bike that's been sitting for 10 years. They are definitely due for a thorough cleaning:

I like to remove the diaphragms and floats before disassembling the carbs as they are fragile and this minimizes the chances of damaging them while disassembling the rack.

To gain access to the diaphragms, begin by removing the four screws securing the throttle cable mount and remove the throttle cable mount:

Next, remove the screws securing the top cover and lift off the cover. If the cover is stuck in place, tap it a few times with the handle of the screwdriver to shock it loose. Beneath the cover is a large spring and the diaphragm/slide assembly:

Lift up the edges of the diaphragm, being extra careful not to tear or damage it. This will free the assembly for removal. Place your finger through the center of the carb and gently press up on the slide. This will free the slide from the carburetor. Lift out the assembly and set it aside where it won't be damaged:

Continue with the rest of the carburetors, removing the top cap and lifting out the slide/diaphragm assemblies:

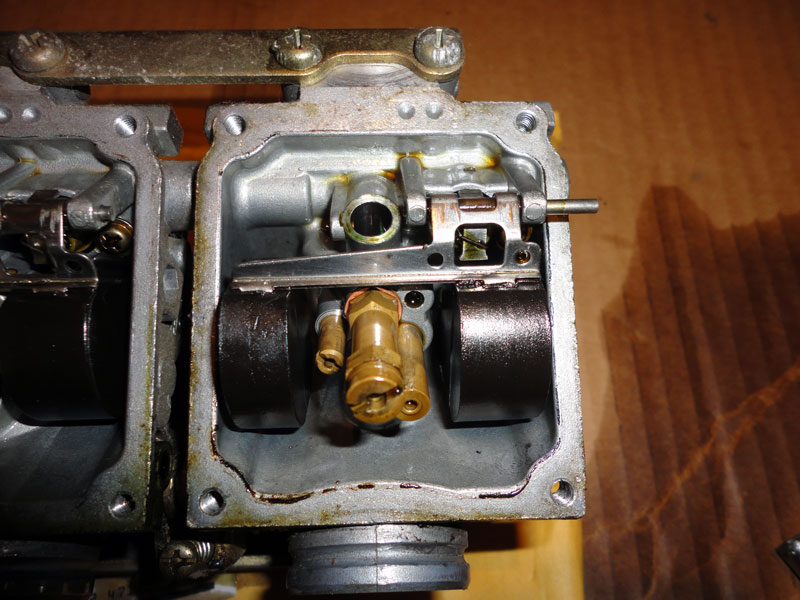

These two slides are stuck solid within the carburetor. I'm tempted to press harder on the slide body but that will risk damaging the diaphragms and slides. If your slides are stuck, remove the float bowl and remove the slides with the emulsion tubes attached:

Once the slides are removed from all four carburetors, turn your attention to the floats. Remove the four Phillips head screws securing the float bowl and lift the bowl off. If the bowl is stuck, tap it with the handle of your screwdriver to remove:

Remove the float bowl from all four carbs (you'll notice that the emulsion tubes are missing from the two carbs with stuck slides; they were removed with the slides):

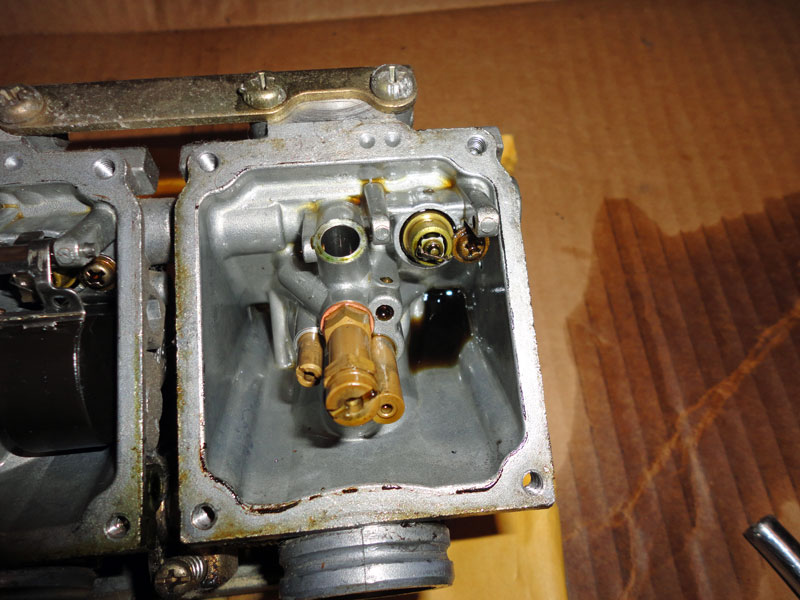

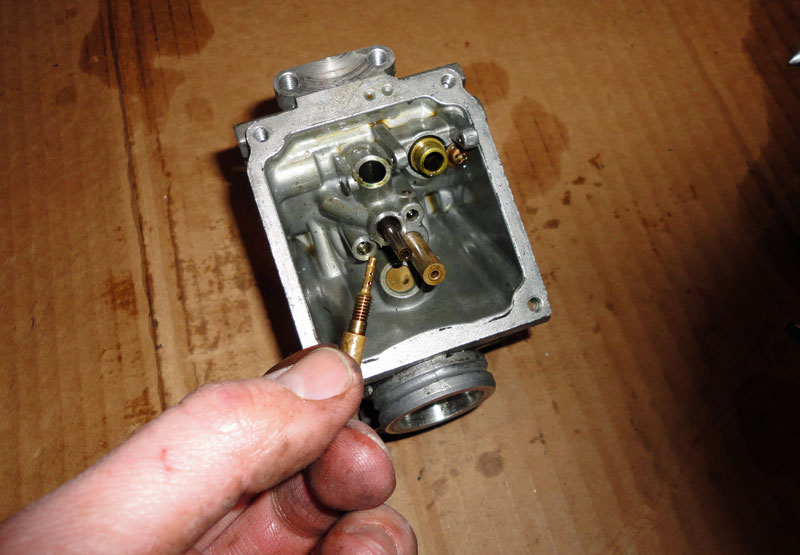

To remove the floats, the emulsion tubes must be removed first. Remove the brass acorn screw securing the tube and tap the tube out of the carburetor (do this with a tool made of wood or plastic but NOT metal; I used a chopstick). If you break the acorn screw, you can find new ones here.:

With the emulsion tubes removed, the float can be removed. The float pivots on a pin which is slid into mounting prongs on the carb body. Remove this by tapping the pin out. If the pin is tight, a 4D finishing nail fits perfectly to tap it out:

Lift the float out and sit it aside. Below the float you'll see the float needle valve:

(At this point, the photos will be a bit out of sequence. I had to disassemble the rail to drive a float pin out as I didn't have ample clearance with them assembled. I've re-sequenced the pictures to make more sense to those who don't have to do this.)

Grasp the needle valve with a pair of needle-nose pliars and pull it out. Sit it aside with the other parts:

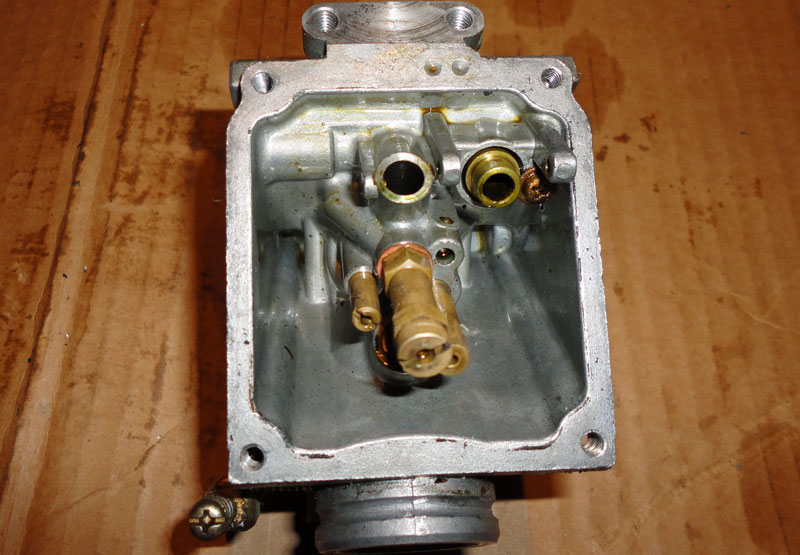

Remove the main jet using a flat-blade screwdriver. The jet holder may unscrew with the main jet or may have to be removed seperately. It requires an 8mm wrench to remove:

Use a flat-blade screwdriver and remove the pilot jet:

Remove the phillips-head screw, grasp the float valve seat and pull it out. It is sealed to the carb body with an o-ring and may offer resistance to being removed. Pull firmly but be careful not to scratch the soft brass seat.

NOTE: When grasping the float valve seat, hold it only by the outside edges. The inside edges run against the float valve needle and if they are damaged, the float needle will likely stick.:

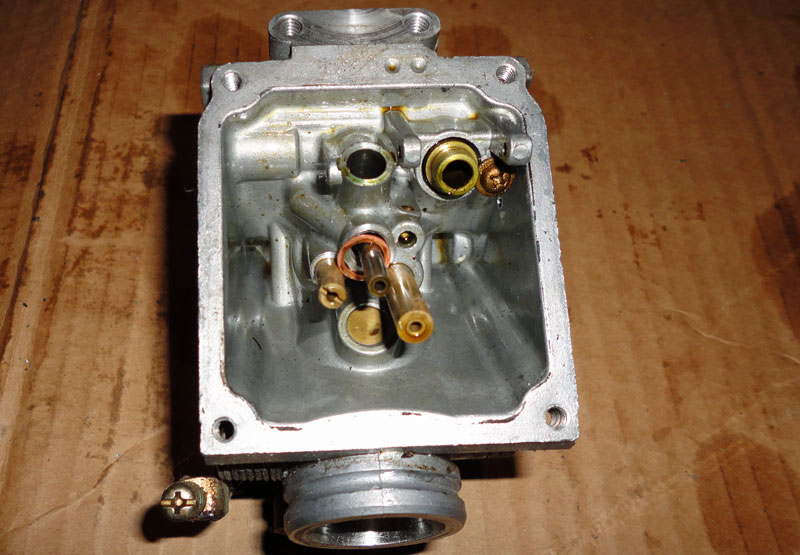

Repeat the same process with all four carbs, removing the float, jets and valve. Once all four carbs are disassembled, seperate them from the rail.

to seperate the carbs from the rail, begin by removing the enrichment lever. This is done by removing the four screws securing it's bracket to the carb:

The enrichment knob is held in place with a c-clip. Remove this c-clip, slide the knob/lever out of it's bracket and pull the bracket off. Remove the actuator rod by loosening the screw at the enrichment plunger on each carb and pull the rod from the assembly:

Remove the screws holding the remainining intake-side rail bracket and remove the bracket. I had problems with these screws loosening so I tapped a screwdriver bit into the screw (gently). This reshaped the screw and the shock helped to loosen the screw:

Flip the rail over and remove the lower bracket by removing the 8 phillips-head screws securing it the carbs:

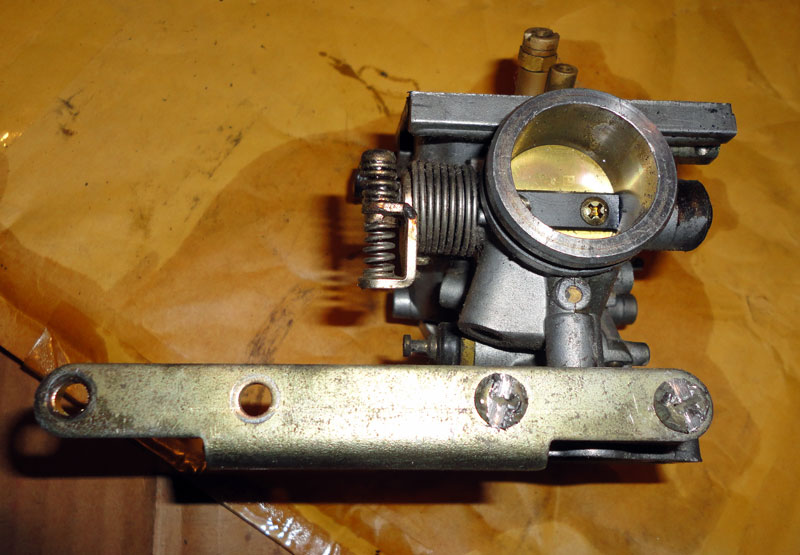

Remove the four screws holding the upper bracket in place and remove the bracket. The carbs should now be free from the rail:

If you're having trouble removing a screw and the vice-grips won't get it either, try cutting a slot in the screw head using a grinder, dremel or hacksaw. This will let you use a flat-head screwdriver and the screws should free up:

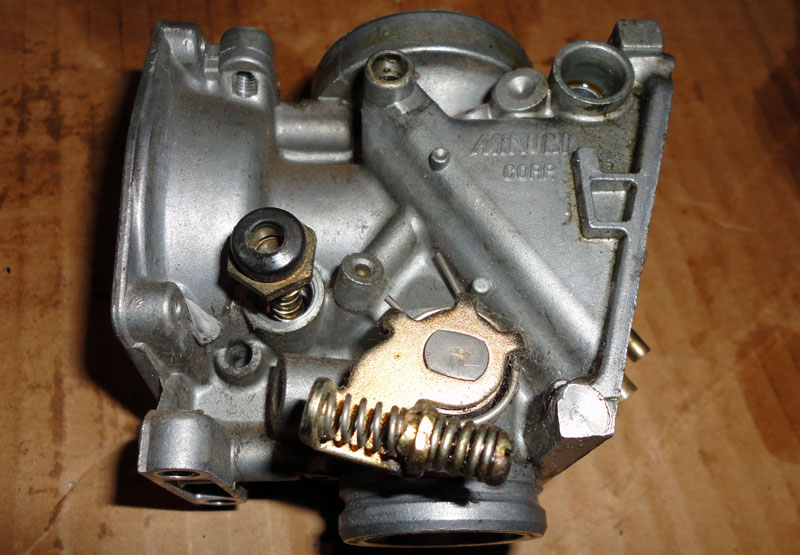

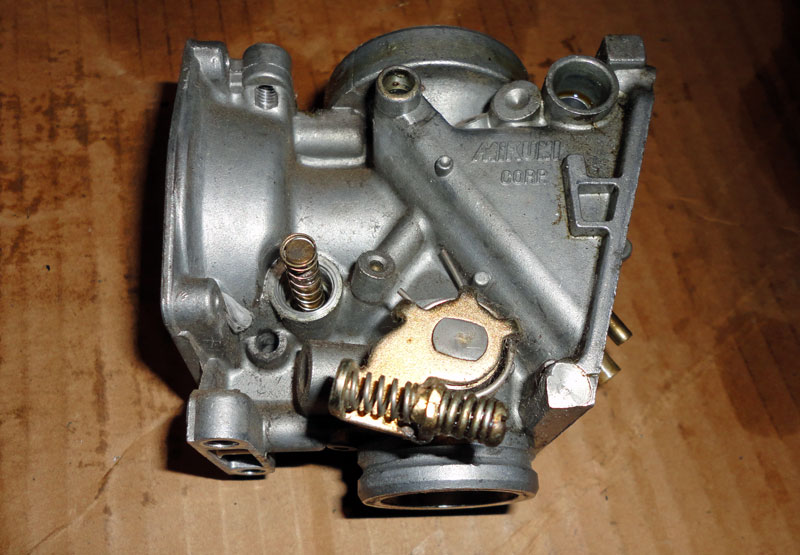

Seperate the carbs by grasping each and pulling them apart. Remove the connector seals and the butterfly springs as they come apart and set aside.

With the carbs seperated from the rail, the last steps in disassembly are to remove the enrichment plunger, remove the butterflies and shaft, and to remove the pilot screws (and EPA plugs).

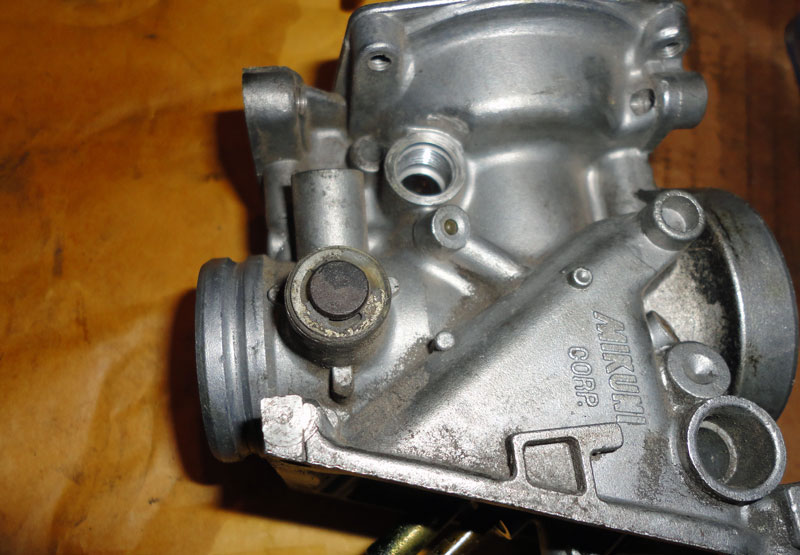

To remove the enrichment plunger, unscrew it and pull it out of the body. Clearance is unusually tight between the 12mm nut on the enrichment plunger and the carb body. To remove this nut, I thinned out a deep-well 12mm socket using an angle grinder until it fit over the plunger:

Loosen the enrichment plunger and unscrew it's retaining nut:

Remove the nut, pull out the spring and plunger and set aside:

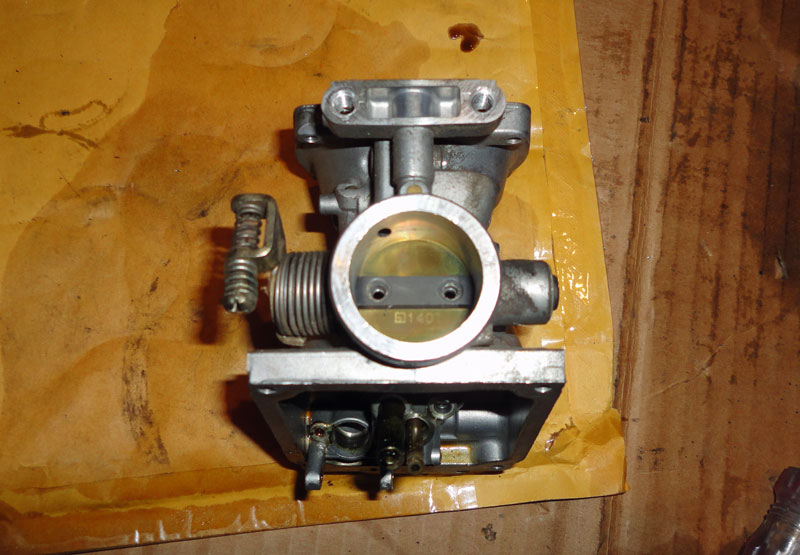

The last part of disassembly is to remove the butterflies and shafts so that we can remove the shaft seals. In my opinion, this is the most difficult step:

Use a very-well fitting phillips-head screwdriver and remove the two phillips-head screws from the butterfly. These screws are staked on their backside (to keep them from loosening and getting sucked into the engine) and are difficult to remove. Be careful and use common sense when backing them out; if it feels like you're deforming the head of the screw, stop and try another approach. I found that lightly tapping the end of the screwdriver to shock the threads of the screw helped them to loosen.

With the screws removed, turn the butterfly sideways and pull it out with your fingers:

Here's a better shot of the difficult to remove butterfly screws, removed

Finally, remove the c-clip and pull the shaft free:

The order of removal for the outside carbs (#1 and #4) is clip, plastic spacer, butterfly-seal, butterfly seal, spring, shaft end:

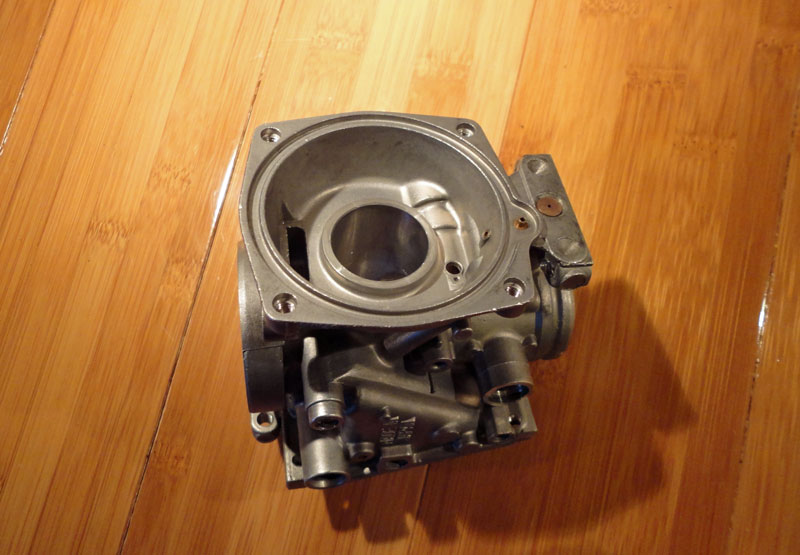

Repeat the same process for the remaining carbs. I'd recommend photographing each disassembly so that you know how it goes back together. Here are my four carbs disassembled:

If your carb still has the pilot screw plugs, they will need to come out and the pilot screws removed prior to cleaning. Here's what the plug looks like:

To remove the plug, drill a very shallow hole (1/4" or less) with a 1/16" drill bit and thread in a michine screw:

Use a pair of Vice-Grips to pull the plug out:

Under the plug is the pilot screw. Screw it in, counting the number of turns until it seats. Write this number down as you'll set the carb back to this position when you're done. Here's the sequence the pilot screw is installed: